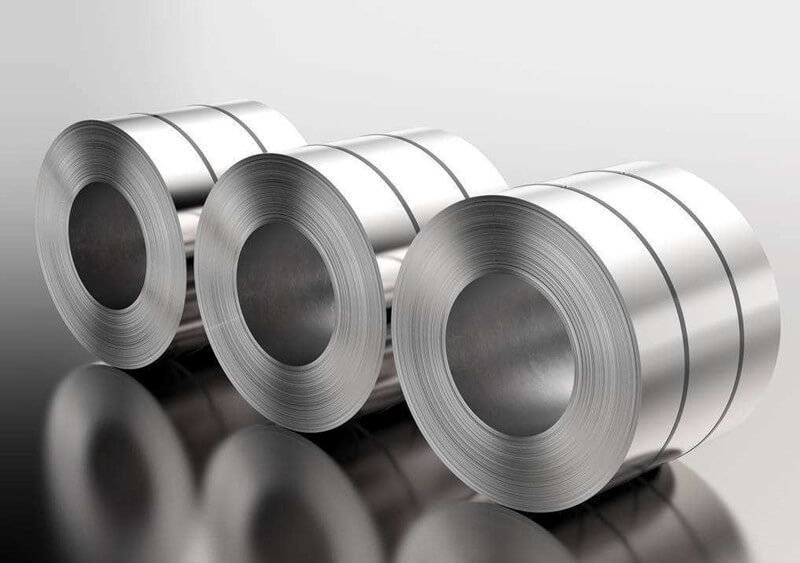

What is Cold-Rolled Steel?

Cold-rolled steel is a fundamental material in various industries, renowned for its unique properties and applications. In this article, we will delve into the world of cold-rolled steel, exploring its composition, production process, advantages, and diverse uses.

Understanding Cold-Rolled Steel – A Comprehensive Guide

Cold-rolled steel is a type of steel that has undergone a cold reduction process, which involves passing the steel through rollers at or near room temperature. This process results in a smoother, more precise, and dimensionally accurate product compared to hot-rolled steel. Cold-rolled steel is often preferred when precision and a polished surface finish are essential.

The Production Process

The production of cold-rolled steel involves several key steps:

- Hot Rolling: Initially, steel is hot-rolled into large coils or sheets. This process eliminates surface imperfections but leaves the steel with a rough finish.

- Pickling: The hot-rolled steel is cleaned using acid to remove oxides and scale from its surface. This step enhances the steel’s surface quality.

- Cold Rolling: The pickled steel is then passed through a series of rollers at room temperature. This cold-rolling process reduces the thickness of the steel while improving its surface finish, flatness, and mechanical properties.

- Annealing: In some cases, the cold-rolled steel undergoes annealing, a heat treatment process that enhances its ductility and removes residual stresses.

Advantages of Cold-Rolled Steel

Cold-rolled steel offers several advantages over its hot-rolled counterpart:

- Surface Finish: Cold-rolled steel boasts a smoother and more polished surface finish, making it ideal for applications where aesthetics matter.

- Dimensional Accuracy: The cold-rolling process provides precise thickness control, ensuring consistent dimensions across the entire material.

- Strength and Hardness: Cold-rolled steel tends to be stronger and harder than hot-rolled steel, making it suitable for demanding applications.

- Tight Tolerances: Manufacturers can achieve tight tolerances with cold-rolled steel, meeting exact specifications.

Applications of Cold-Rolled Steel

Cold-rolled steel’s versatility makes it indispensable in various industries:

- Automotive: Used for vehicle body panels, structural components, and engine parts.

- Construction: Employed in roofing, cladding, and the production of steel framing members.

- Manufacturing: Vital for appliances, machinery, and metal furniture production.

- Electronics: Utilized in the production of electronic components, enclosures, and appliances.

- Packaging: Forms the basis for tinplate used in food and beverage packaging.

- Home Improvement: Commonly used in household items like sinks, faucets, and door hardware.

Cold-rolled steel’s precision, strength, and polished finish make it an invaluable material in countless applications across multiple industries. Understanding the production process and the advantages it offers allows engineers, designers, and manufacturers to make informed choices, ensuring the success of their projects. Whether you encounter it in your daily life as a consumer or use it in your professional endeavors, cold-rolled steel continues to play a crucial role in shaping our modern world.

Sustainability and Cold-Rolled Steel

In addition to its various advantages, cold-rolled steel aligns with sustainability goals in several ways:

Recyclability: Cold-rolled steel is highly recyclable, contributing to reduced waste and resource conservation. When products made from cold-rolled steel reach the end of their life cycle, they can be recycled efficiently without compromising quality.

Energy Efficiency: The cold-rolling process consumes less energy compared to hot rolling. This energy efficiency contributes to a lower carbon footprint in the steel manufacturing industry.

Durability: Products made from cold-rolled steel tend to have a longer lifespan due to their resistance to wear and corrosion. This durability reduces the need for frequent replacements, further conserving resources.

Reduced Material Waste: The precise control over dimensions during the cold-rolling process minimizes material waste, making it a cost-effective and eco-friendly choice.

The Future of Cold-Rolled Steel

As industries continue to emphasize sustainability and precision, the demand for cold-rolled steel is expected to grow. Advances in technology and metallurgy are likely to lead to even more efficient production methods and new applications.cold-rolled steel’s unique characteristics, production process, and eco-friendly attributes make it an essential material in today’s world. Whether it’s found in your car, your home, or the products you use daily, cold-rolled steel’s contribution to precision, strength, and sustainability is undeniable. As industries evolve and embrace greener practices, cold-rolled steel will undoubtedly play a significant role in shaping a more sustainable and efficient future.